-

LICHUANG BEVERAGE PACKAGING AUTOMATION EQUIPMENT

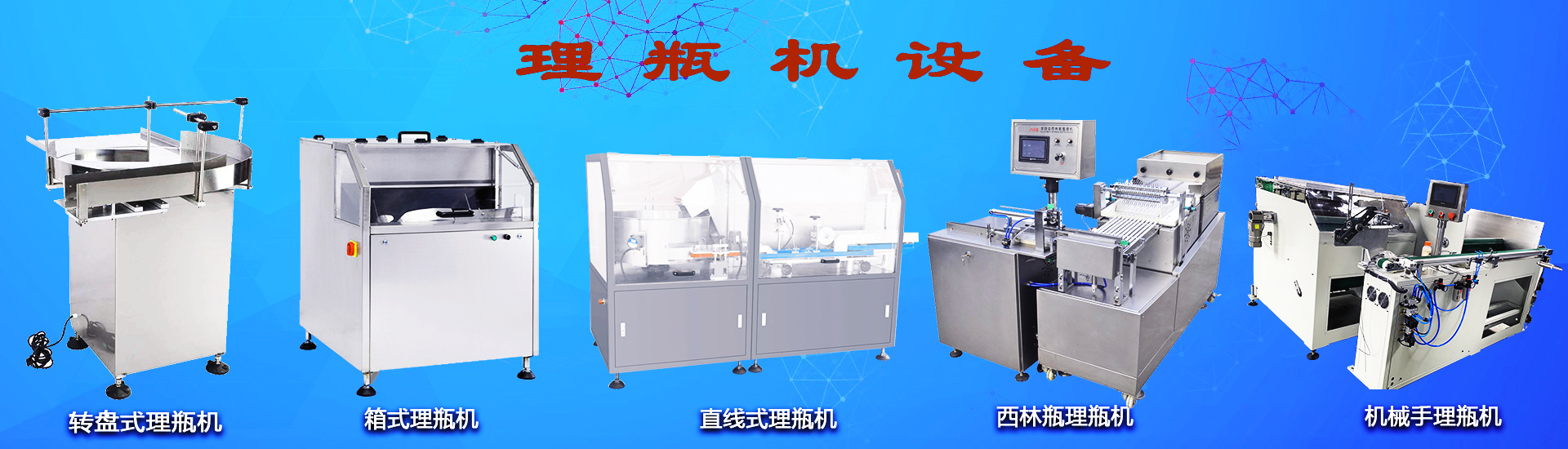

全自动理瓶机

饮料生产线-矿泉水生产

适合瓶型:

圆瓶、方瓶、扁瓶、曲线瓶、锥形瓶、异形瓶等;10ml-4l,可根据您的需要而定制设备。

Applicable

Bottle Types

Applicable

Bottle Types

Round bottles, square bottles and flat bottles, curve, conical flask, special-shaped bottle, etc.

全自动理瓶机 LC-PBMP

AUTOMATIC BOTTLE UNSCRAMBLER

本机是全自动理瓶机,适用于灌装前段工序,可将杂乱无章的PET塑料瓶整齐的排列到输送线上,稳 定可靠.理瓶效率高,适应性强。

• 适用多种瓶型,数字可视化,傻瓜式轻松调整,一机多用,避免繁琐更换模具,节省投资

• 采用优质不锈钢材质,设备核心电气元件均采用plc 丹佛斯 sew,性能更加稳定

• 全触摸屏操作系统,智能化设计,轻松操作

• 特殊结构提升系统,入瓶率更高,瓶损率更低

• 卡瓶、堵瓶、空瓶检测装置,能有效保护机器安全

• 不用压缩空气,减少瓶子二次污染

This machine is a automatic unscramble bottle machine, suitable for filling the front process, desultorily PET plastic bottles can be arranged in the conveying line. This machine is high configuration high-performance unscramble bottle machine, designed for high-performance production and design of production line

• suitable for a variety of bottle type, data visualization, easy-to-install easy adjustment, multi-usage, avoid cumbersome change mould, save the investment

• Core, USES the high quality stainless steel material, equipment, electrical components adopt high-end international brand, PLC and screen adopts siemens , frequency converter adopts the danfoss brand, motor

adopts the SEW brand, more stable performance.

• Full touch screen operation system, intelligent design, fool operation, more simple

• Original hoisting system of the special structure, the taking bottle rate is more higher and the damaged bottle rate is lower

• Bottle plugging, empty bottle detection device, can effectively protect the security of the machine, at

• Without compressed air, reduce the secondary pollution bottle

主要技术参数

型号

C-PM BM -12

C-PM BM -15L

C-PM BM -IB

主机尺寸Size of host machine(m)

①2.0米X1.9米

少2.2米X1.9米

①2.4米X1.9米

瓶身直径 Applicate diameter of bottle body(mm)

①55-75(常规)

055-75(常规)

055-75(常规)

瓶身高度 Height of the bottle(mm)

140-230

140-230

140-230

适配灌装机Matching filling machine

24-24-8

32-32-10

40-40-12

生产速度Product speed (B/H)

12000

15000

18000

电压 Voltage(V)

380

380

380

输入功率Input power(KW )

2.2

2.2

2.5

设备重量Weight(Kg)

1000

1200

1500

.特殊瓶型可定制

全自动智能一键理瓶机 LC-AUPJ

AUTOMATION INTELLIGENT ONE-BUTTON BOTTLE UNSCRAMBLER

本机是全自动理瓶机,适用于灌装机前段工序,可将杂乱无章的PET塑料瓶整齐的排列到输送线上。本机是 高配置高性能理瓶机,专为高性能产线生产而设计。

一键启动,傻瓜式操作

• 高速推进装置

• 特殊结构提升系统,入瓶率更高,瓶损率更低

• 卡瓶' 堵瓶, 空瓶检测装置,能有效保护机器安全

• 不用压缩空气,减少瓶子二次污染

• 波浪式翻瓶装置,摆针式校瓶装置

• 适用多种瓶型,一键调整,一机多用,节省投资

•采用优质不锈钢材质,设备核心电气元件均采用plc 丹佛斯 sew,PLC和触摸屏采用西门子品牌,

变频器采用丹佛斯品牌,电机采用SEW品牌,性能更加稳定

, Push-button start

, Original high-speed propulsion system

, Original hoisting system of the special structure, the taking bottle rate is more higher and the damaged

bottle rate is lower

• Bottle plugging and empty detection device, can effectively protect the security of the machine

• At first without compressed air, reduce the secondary bottle pollution rate

• Wave bottle device, pin type adjusting bottle device

• Suitable for a variety ofbottle type, and the easy adjustment, multi-usage, save investment

主要技术参数

型号 jfpe C-AU PJ-12 C-AU PJb15 C-AU PJ-U

主机尺寸Size of host machine(m)

①2.0米X1.9米

①2.2米X1.9米

①2.4米X1.9米

瓶身直径 Applicate diameter of bottle body(mm)

050-70(060-80)

050-70(060-80)

050-70(060-80)

瓶身高度 Height of the bottle(mm)

140-240

140-240

140-240

适配灌装机Matching filling machine

24-24-8

32-32-10

40-40-12

生产速度Product speed (B/H)

12000

15000

18000

电压 Vo It age (V)

380

380

380

输入功率Input power(KW )

1.8

1.8

2.0

设备重量Weight(Kg)

1200

1400

1500

*特殊瓶型可定制

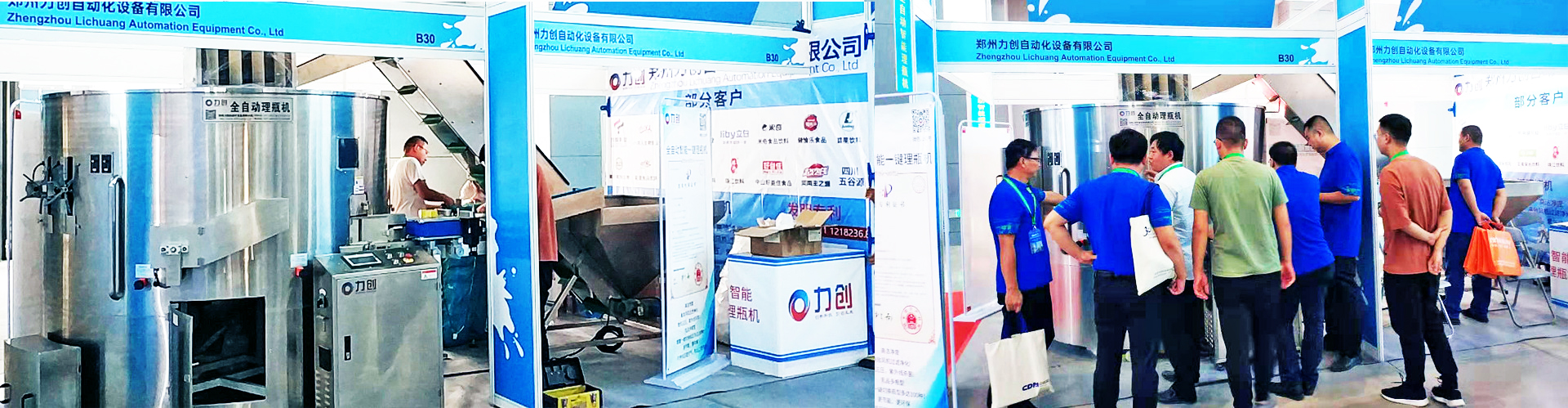

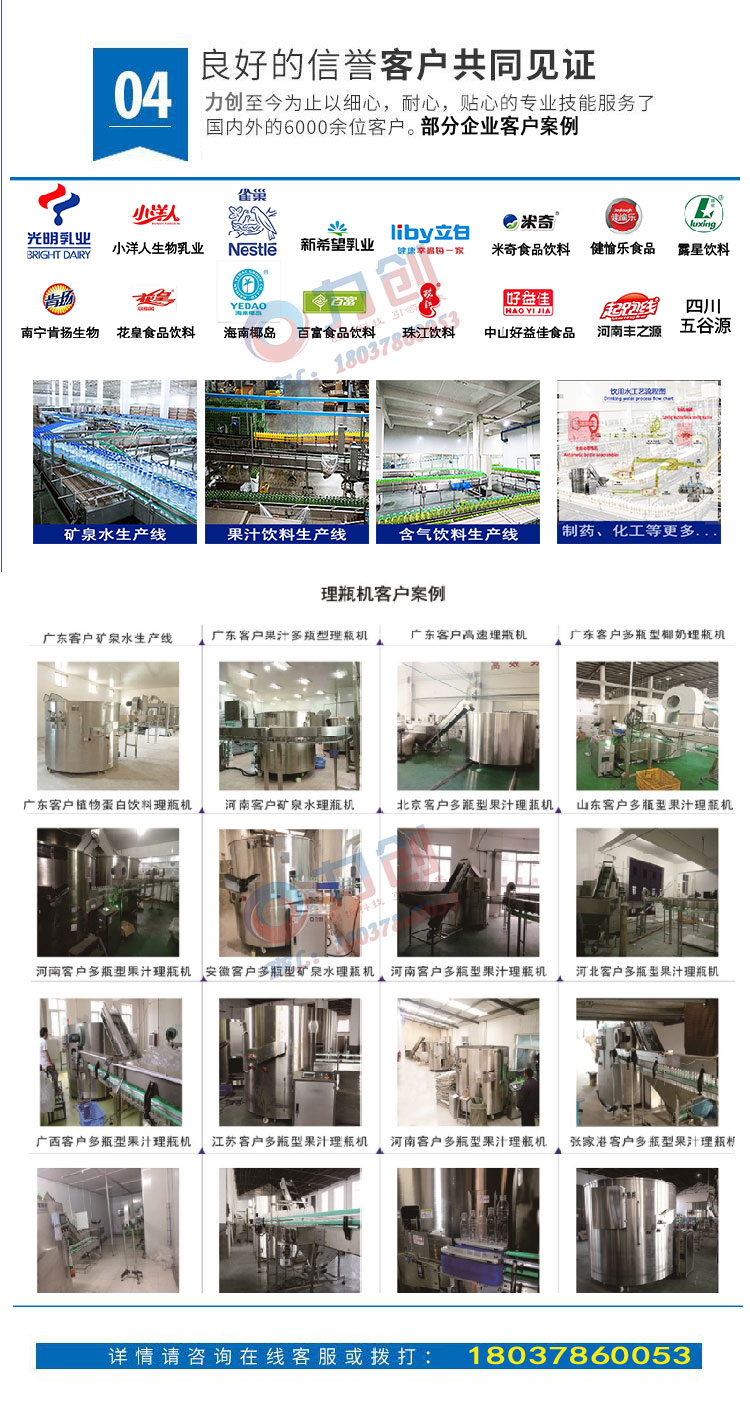

企业简介

COMPANY PROFILE

河南郑州力创自动化设备有限公司成立于2012年,坐落于河南郑州市荥阳龙港工贸园。

力创是一家专业从事饮料包装设备的非标自动化设计和制造企业,致力于提高产线的自动化程度,降低人 力成本,为客户提供优质服务。业务范围涉及饮料工程、酒类工程、食品工程、乳品工程、生物制药、物流运 输、化工保健品和水处理等工程领域。

郑州力创自动化设备有限公司为客户提供各类饮料产线的交钥匙工程,并研发制造高效智能全自动理瓶 机,全自动热收缩膜套标机、全自动瓶口套标机、全自动热收缩膜包装机、全自动贴标机、缩标炉、喷淋杀菌 机、风刀机、无压力输送系统等设备。

公司先后与百事可乐、可口可乐、完达山、森氏饮用水、河南丰之源、德荣牛肉、中山珠江饮 品、健愉乐、光明乳业、小洋人、百冠、立白、米奇等众多企业建立了良好的合作关系,优良的设备和良好的 信誉使得上海、张家港、江苏、贵州、广州、河南等各地都有我们的经销商和代理伙伴。

Zhengzhou Lichuang Automation Equipment Co. , Ltd. was founded in 2012, is located in Xingyang Longgang Industrial and Trade Park, Zhengzhou City, Henan Province.

The company is a professional engaged in beverage packaging equipment, non-standard automation design and manufacturing company, is committed to improve the degree of automation of the production line, reduce labor costs, to create maximum value for customers. The scope of business involves beverage engineering, wine engineering, food engineering, dairy engineering, bio pharmaceuticals, logistics and transportation, chemical health care products and water treatment engineering.

The company provide all kinds of beverage production line of turnkey projects for customers, and R & D and manufacturing efficiency of intelligent automatic bottle machine, automatic heat shrink sleeve labeling machine, automatic bottle labeling machine, automatic shrink film packaging machine, automatic labeling machine, shrink air knife furnace spray steri1ization machine, machine, pressure free conveying system.

The company has a good relationship with Pepsi Cola, Coca-Cola, Wandashan, Sen s drinking water, Shijin international, Henan Fengzhiyuan, de Rong beef, Zhongshan Pearl River drinks, health recreation,Guangming Dairy, Xiao Yang Ren. Baiguan, Libai, Mickey, Hainan Coconut Is1 and and many other enterprises to establish, exce11 ent equ i pment and good reputat ion i n Shanghai, Zhangj i agang, J i angsu, Guizhou, Guangzhou, Henan and other city with our dealer and partners!

Innovat i on and technology, leading the future! Zhengzhou force to create a people-or i ented with the credibility of the escort to i nnovat i on as the driving force, and constantly provide customers wi th first-class value of equ i pment and services, and strive to create a brill!ant beverage enteror i ses!

河南省饮料协会会员

The member of Henan Beverage Association

河南省水处理协会会员

The member of Henan Water Treatment Association

饮料生产及包装合作伙伴

The partner for beverage production and packaging

― 区实图 The factory will

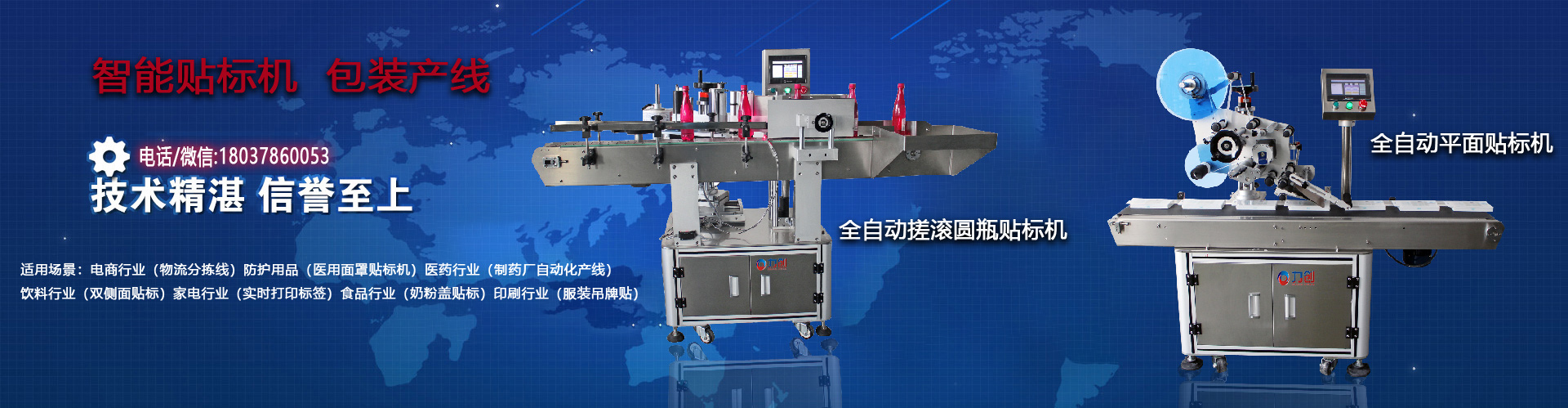

- 本机是全自动理瓶机,适用于灌装前段工序,可将杂乱无章的PET塑料瓶整齐的排列到输送线上,稳 定可靠.理瓶效率高,适应性强。

• 适用多种瓶型,数字可视化,傻瓜式轻松调整,一机多用,避免繁琐更换模具,节省投资

• 采用优质不锈钢材质,设备核心电气元件均采用plc 丹佛斯 sew,性能更加稳定

• 全触摸屏操作系统,智能化设计,轻松操作

• 特殊结构提升系统,入瓶率更高,瓶损率更低

• 卡瓶、堵瓶、空瓶检测装置,能有效保护机器安全

• 不用压缩空气,减少瓶子二次污染

This machine is a automatic unscramble bottle machine, suitable for filling the front process, desultorily PET plastic bottles can be arranged in the conveying line. This machine is high configuration high-performance unscramble bottle machine, designed for high-performance production and design of production line

• suitable for a variety of bottle type, data visualization, easy-to-install easy adjustment, multi-usage, avoid cumbersome change mould, save the investment

• Core, USES the high quality stainless steel material, equipment, electrical components adopt high-end international brand, PLC and screen adopts siemens , frequency converter adopts the danfoss brand, motor

adopts the SEW brand, more stable performance.

• Full touch screen operation system, intelligent design, fool operation, more simple

• Original hoisting system of the special structure, the taking bottle rate is more higher and the damaged bottle rate is lower

• Bottle plugging, empty bottle detection device, can effectively protect the security of the machine, at

• Without compressed air, reduce the secondary pollution bottle